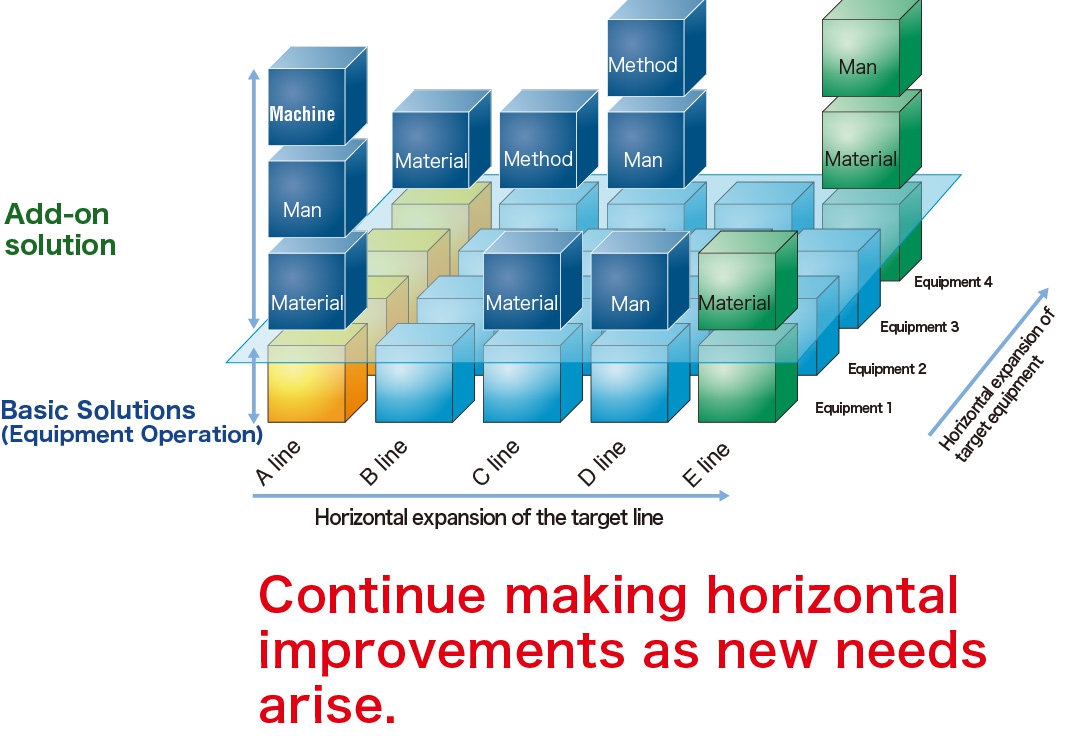

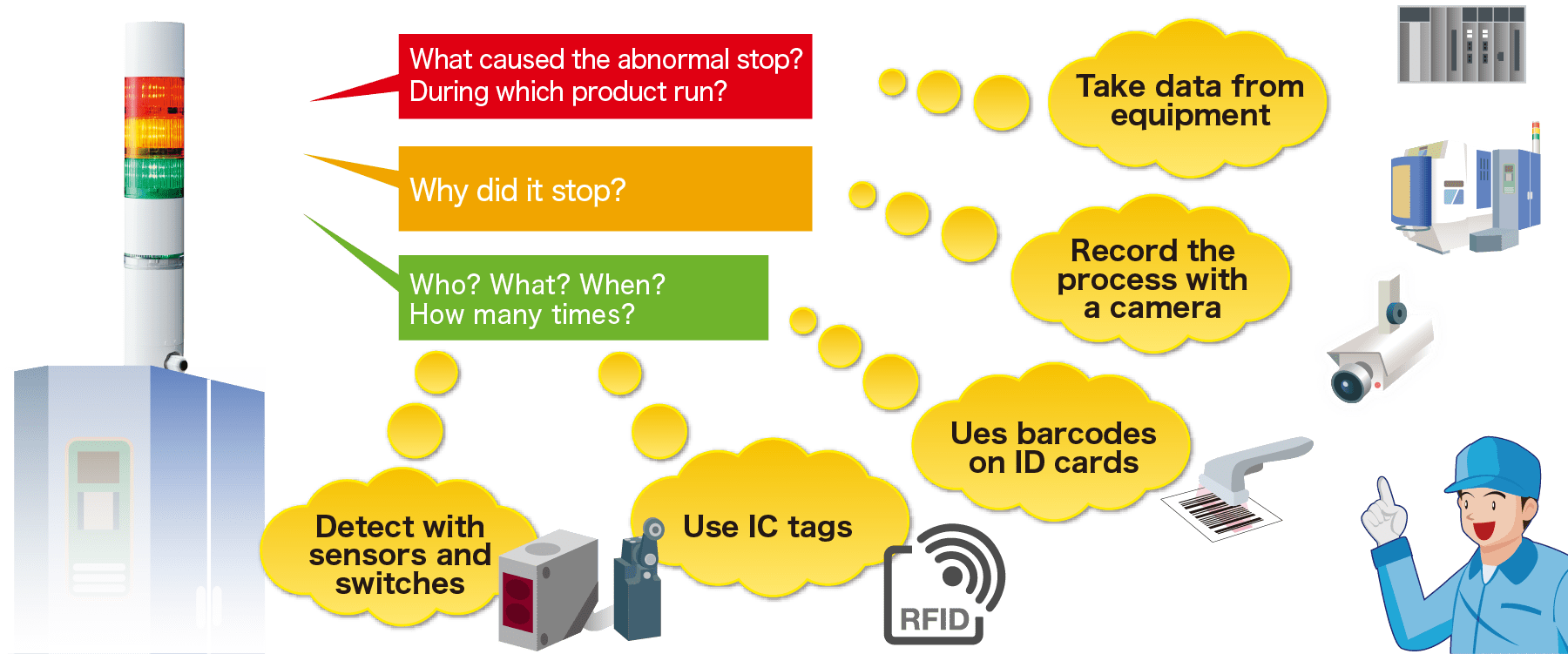

A successful facility should have the ability to measure and analyze precise operations of its equipment. In addition, the "4Ms" should be taken into consideration. The 4Ms of production include:

Man, Machine, Material, Method,

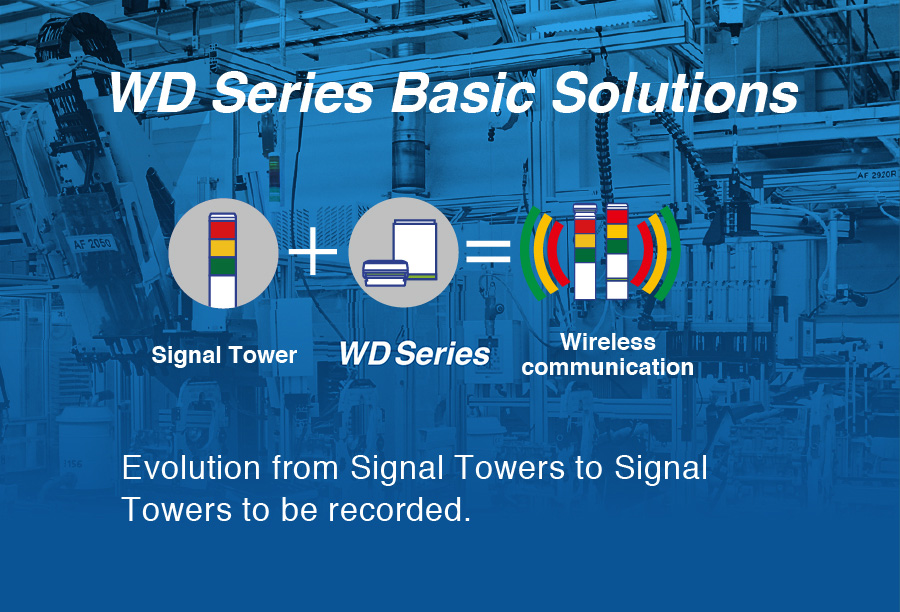

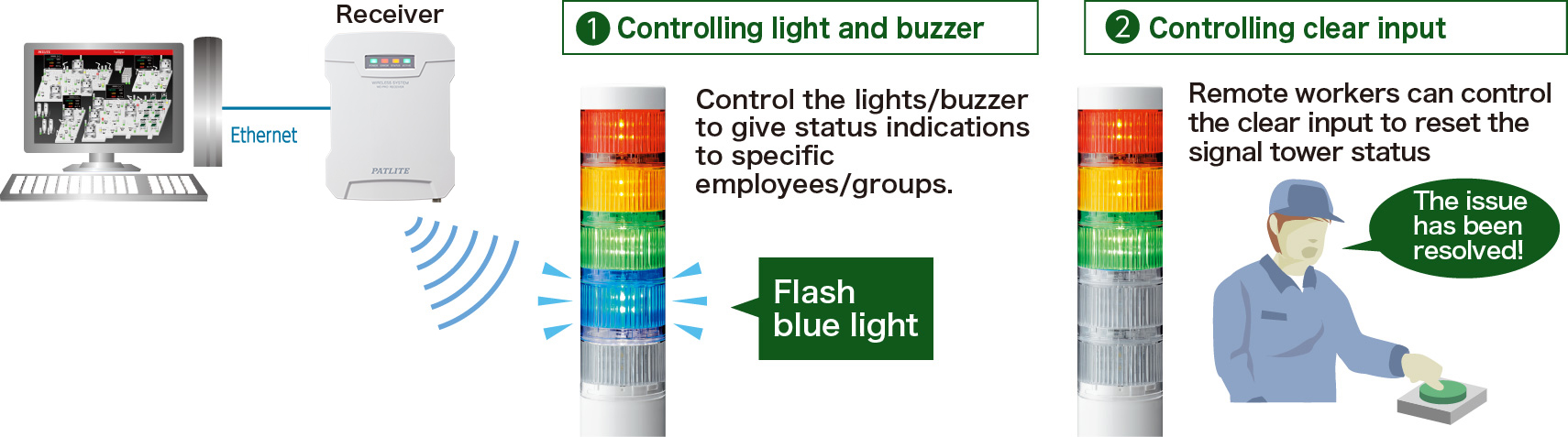

The WD System enables data collection of all of these factors.

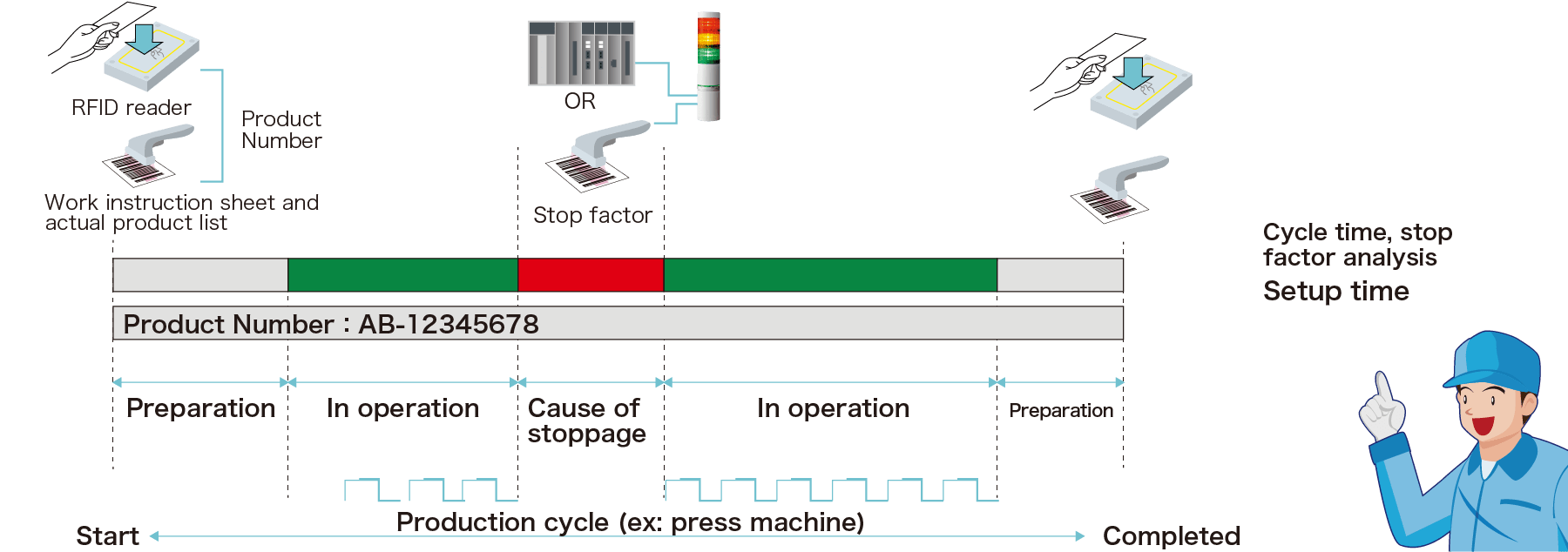

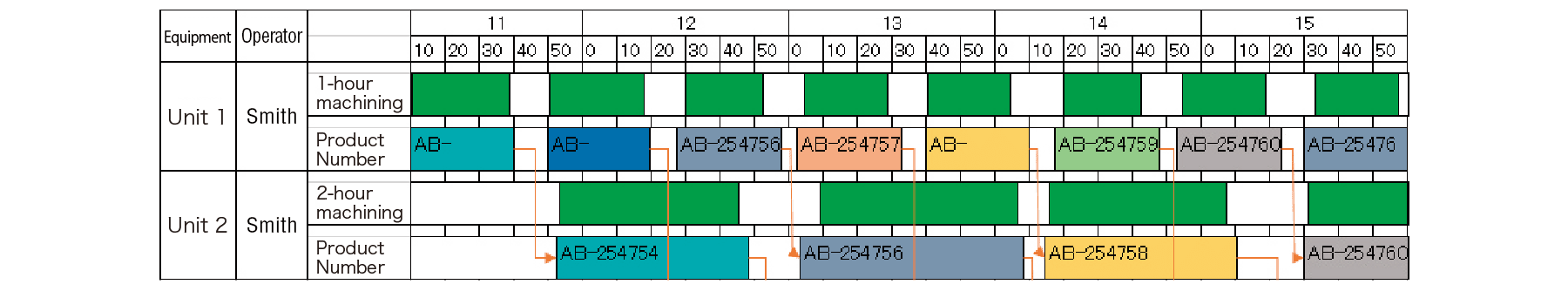

Visualize cycletime, cause of stoppage, and setup time

Enables traceability

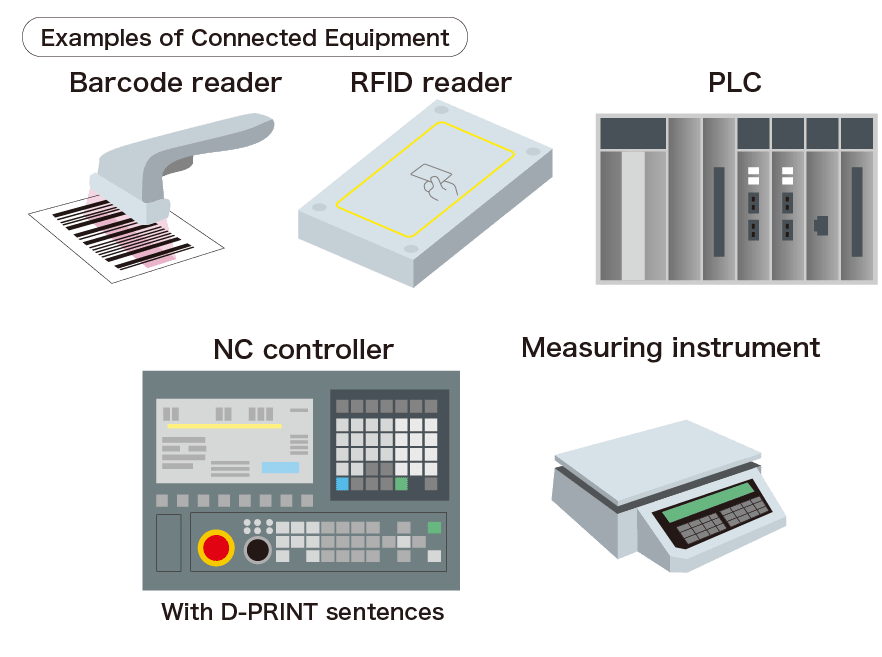

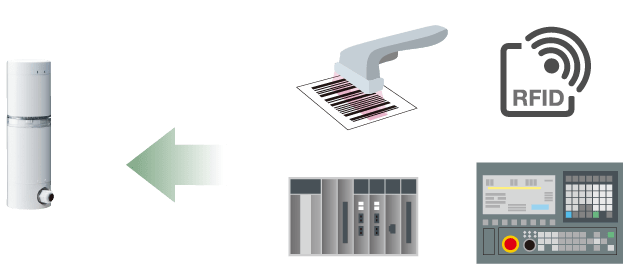

This data capturing system is exclusive to DENSO WAVE [AT20B-SM (R) type and AT21B-SM (R) type].

Sends 60 bytes of data from the data area to the host.

This data capturing system is for general barcode readers, not specific to any company.

Sends 60 bytes of data from the data area to the host.

※ Some barcode readers are not supported.

Sends 60 bytes from the data collected by RS-232C to the host.

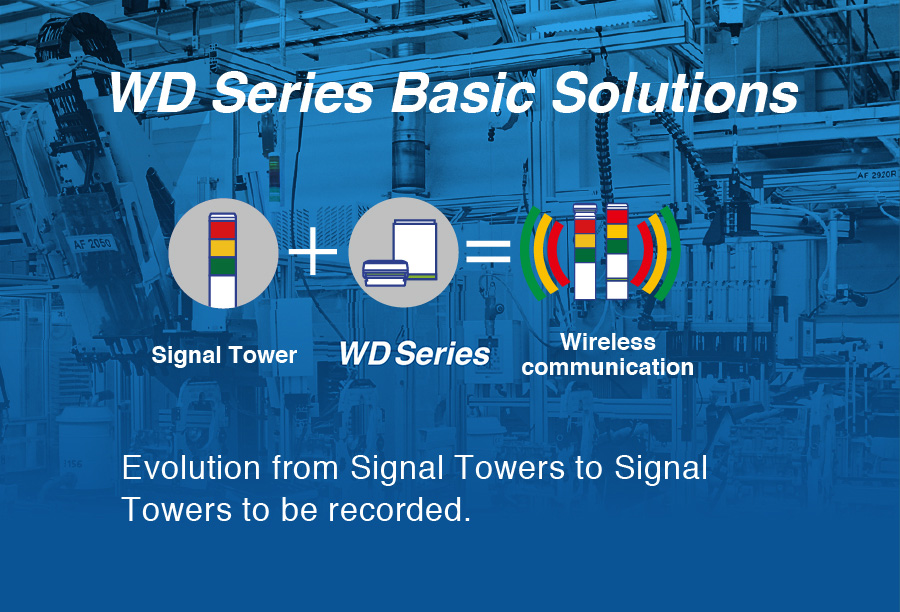

Automatically collect and analyze equipment operation data.

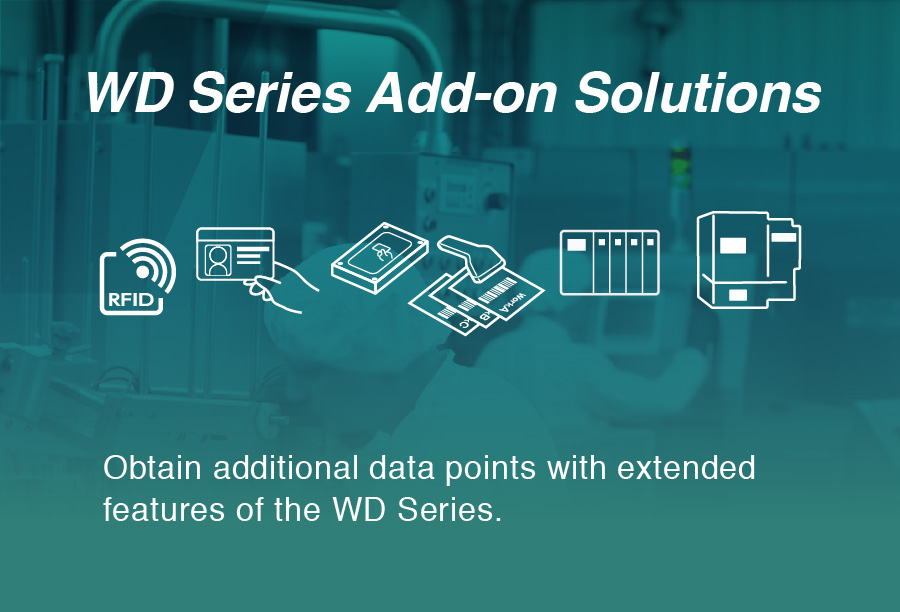

Trace and manage materials and workers.

Ex: Progress control, quality control, equipment occupancy time per material, etc.

Automatically collects operational details such as setup and assembly.

Ex: Preparation time, assembly work analysis, proficiency evaluation, work improvement, etc.

Automatically collects and record equipment error codes.

Ex: Equipment stoppage Pareto analysis, equipment renovation, productivity improvement, etc.

Automatically collects values such as work in process, number of defects, etc. to assist in analysis of bottlenecks and defect rates.

Ex: Production progress management, cycle time analysis, productivity improvement, prolonging equipment life, etc.

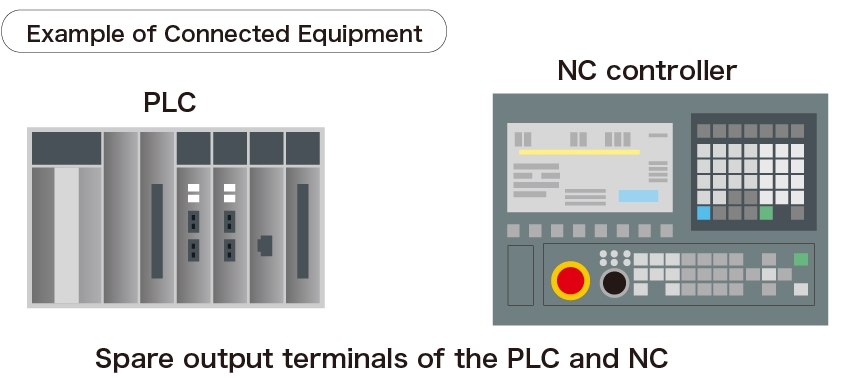

Automatically collects equipment/operational metrics to reduce the burden of manual recording.

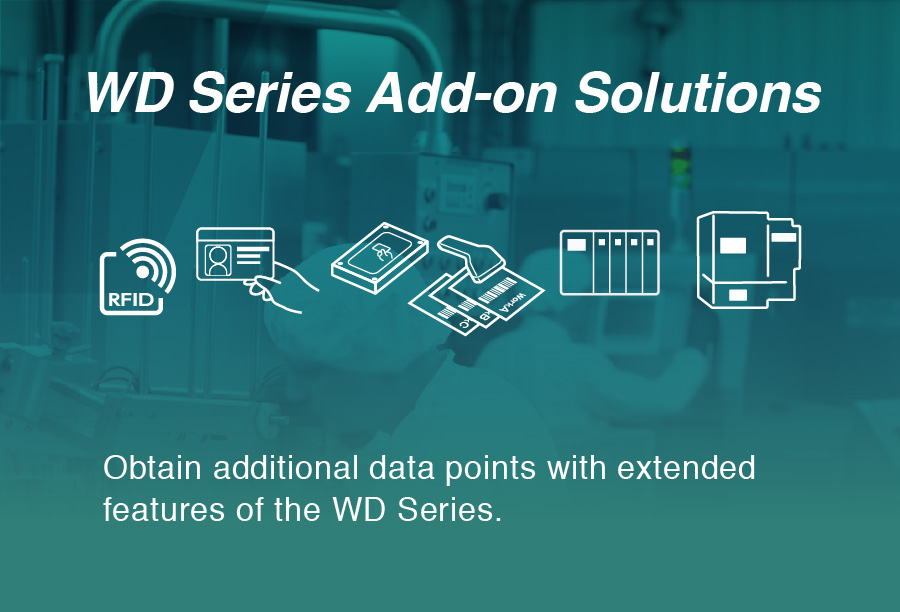

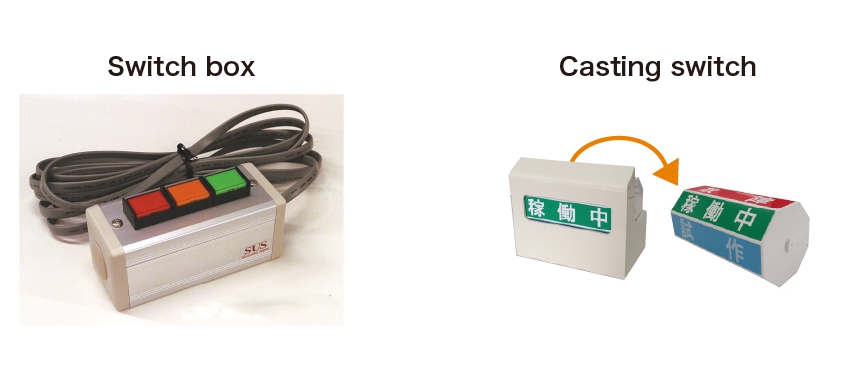

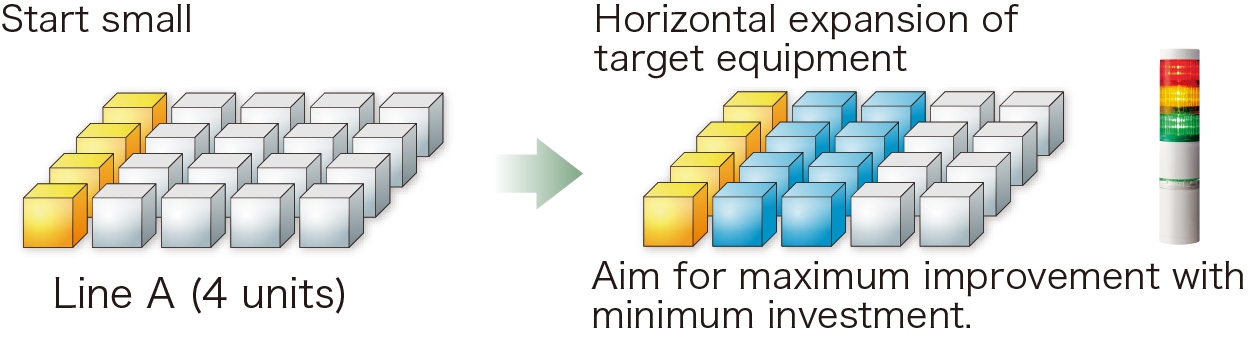

Implement add-ons as new requirements appear, making sure to add only what is necessary.

1Case-by-case installation

Add-ons implemented only when it is needed

WD PRO

(without Signal Tower)

2Permanent installation

WD PRO

with Signal Tower